BENE - competent, personal support. We look forward to hearing from you.

Total Cost of Ownership

The actual price of a product is often recognisable after its first use. In addition to the purchase price, consumable products during operation represent additional costs, which can be calculated prior to the purchase in the best possible cases. The sum of all of these costs (operation, inspection, maintenance, etc.) are referred to as the 'total costs of ownership' or the overall operating costs, and their analysis according to the total cost of ownership analysis or operating cost analysis.

This analysis frequently functions as a planning instrument or decision-making for any form of investment in capital goods to find the most profitable solution. However, the total cost of ownership analysis is especially important for products that result in high maintenance and operating costs during their life cycle. This also includes a number of products on the separator market.

The total cost of ownership analysis involves a pure cost analysis. Other strategic criteria are neglected, but they must always be considered separately during decision-making.

Low price ≠ low cost

Supposedly low-price offers often mutate into costly traps. This can able be observed on the separator market. Due to the high number of providers, it may be assumed that there are drastic differences in terms of equipment, design, etc., among the various systems. All of these aspects must be considered when purchasing a separator system, and the costs must be included in the calculation.

Basically, conventional separators may be considered exceptionally low-cost in terms of their purchasing costs. The operating costs (including maintenance, disposal, renovation), on the other hand, are relatively high. Especially in case of faults, which may be discovered over the course of prescribed general inspections every five years, they frequently need to be renovated at high financial cost.

You should consider the following costs when purchasing your separator:

- Personnel costs for maintenance and renovation

- Personnel and material costs for filter maintenance/cleaning

- Material costs for replacing filters and disposal

- Costs for floater gauge maintenance

- Costs for maintenance of the warning system

- Disposal costs of separator contents for maintenance purposes

- Renovation costs for coating and shaft structures

- Lost revenues due to standstill for maintenance purposes, etc.

Commercial effectiveness

BENE high-performance separators feature a building block system, which definitely results in the lowest disposal costs. For this reason, the additional costs of the BENE system are amortised after a short time.

Oil tank disposal instead of complete emptying: Thanks to disposal of sludge and oil isolated from the separator area, the cost effectiveness of BENE systems is ensured.

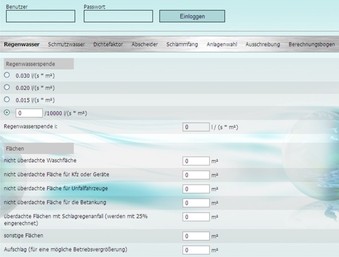

Depiction of an application example. Please ask us for a cost calculation arranged according to your project.